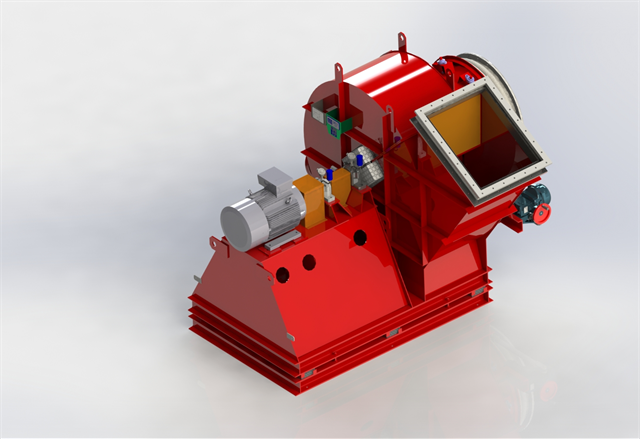

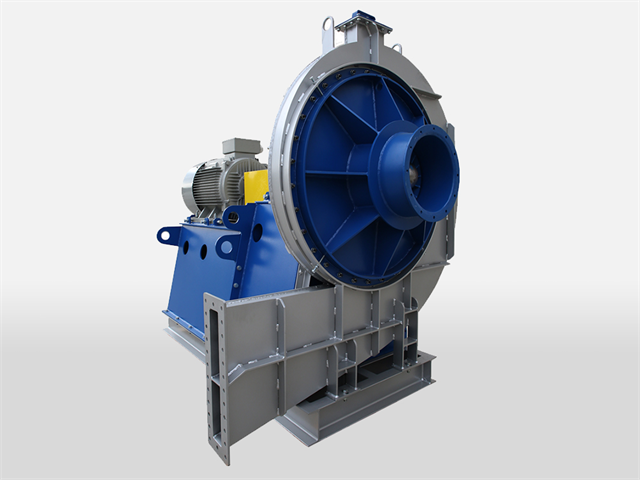

TURBOFANS HP SERIES

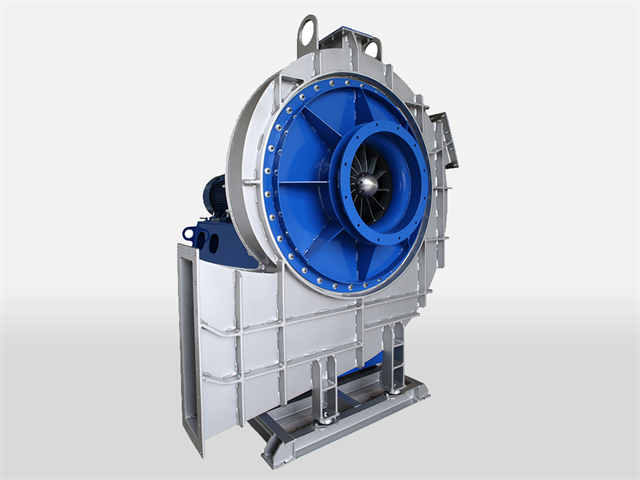

Turbofans type HP are designed for very high pressure and medium flow rate applications. Turbafans has a unique impeller innovative design (diameter of up to 2000 mm) which leads to static efficiencies up to 85%. This innovative design differs from current canonical centrifugal ones, allowing the flow to go through the impeller free of turbulences,thus improving aerodynamic efficiency and reducing mechanical loses

Model: TURBOFANS HP SERIES

Manufacturer : Aeromeccanica Stranich s.p.a. a socio unico

- Specification

- Description

Turbofans type HP are designed for very high pressure and medium flow rate applications.

Turbafans has a unique impeller innovative design (diameter of up to 2000 mm) which leads to static efficiencies up to 85%.

This innovative design differs from current canonical centrifugal ones, allowing the flow to go through the impeller free of turbulences,thus improving aerodynamic efficiency and reducing mechanical loses.

By limiting the rotational speed, we allow for 15% energy savings in comparison with existing products in the market.

The BDC impeller has 13 backwardly curved blades.

Turbofans can be manufactured using different kind of materials, including carbon steel, stainless steel and alloy steel.

Stranich proposes also special solutions with speed rates up to 6000 rpm, using special motors, variable speed drive, gearbox or pulleys and belts.

Turbofans are destined to achieve a pressure rise by adding kinetic energy to a continuous flow of fluid through the rotor or impeller. This kinetic energy is then converted to an increase in potential energy by slowing the flow through a diffuser. The pressure rise in the impeller is in most cases almost equal to the rise in the diffuser section.

STRANICH concept: Stranich has developed a new “turbofan”, which has a unique impeller design with a diameter of up to 2000 mm. It obtains speeds of 3000 rpm plus, avoiding turbulences and mechanical losses, while handling a static differential pressure of over 100mbar@80°C. By limiting the rotational speed, we allow for 15% energy savings in comparison with existing products in the market. Yet we still maintain the pressure required (over 15,000 Pa).

The very core of our solution lies in assessing an alternative design for one of the key components of the turbofan, the impeller. It consists of a new cylindrical in-let with improved centrifugal channels. This innovative design differs from current canonical centrifugal ones, allowing the flow to go through the impeller free of

turbulences, thus improving aerodynamic efficiency and reducing mechanical loses

. In this way, we have prototyped and tested a new “turbofan” which has a diameter up to 1600 mm but also, a new structure design to obtain a speed of 3000 rpm or more, handling a static differential pressure over 100mbar @80°C. We will consistently reduce the absorbed power resulting in a decrease of energy consumption up to 15% more than the existing competitors in the market for similar applications.

A first prototype has been tested with positive result. The total efficiency achieved, in fact, is around 85 %.